Packland Robot Palletiser

The Packland Robot Palletiser is the optimal solution for palletising pails, (open top) boxes, cans, etc. Packland uses an ABB IRB 660 4-axis robot. This robot, with a lifting capacity of 180 – 250kg, in combination with a gripperhead developped by Packland makes for an efficient palletiser.

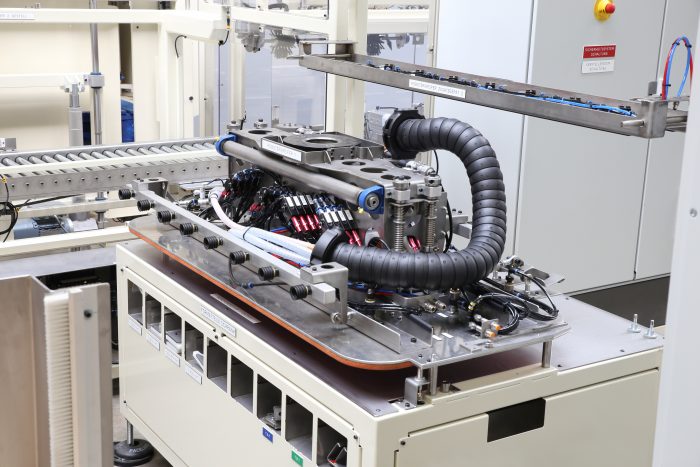

Packland offers robot palletisers with a variety of three different end of arm tools:

- The Packland Vacuum head is ideal for palletising pails. The unique, by Packland developped, vacuum system ensures optimal spread of the lifting force on the bucket and allows for a wide variety of buckets to be picked up with a single tool.

- The Packland Clamping head uses a support plate on which the products sit, in combination wit a clamping plate to clamp the products. When in position above the pallet, the support plate is pulled from underneath the product. This tool is outstanding for cylindrycal cans/tins and (open top) boxes

- The Packland Combi head combines both gripping principles in one tool. When palletising pails the vacuum tool is used, for the other products the support plate with clamping plate is used.

All robot end of arm tools can be equipped with arms to grab pallet tie sheets, grippers to grab foil tie sheets and an automatic tool changer.

The type of in feed of products is fully dependent on the nature and range of the products to be palletised. Accumulating roller conveyors can be used for round/rectangular pails, cans/tins and (open top) boxes. For smaller products a flat belt conveyor will be used. Besides this, Packland has solutions for palletising oval buckets, even if they need to be at an angle. For this servo driven conveyors are used to ensure perfect positioning and placement of the products.

For round pails and cans/tins with handle the line will be equipped with an orientator. In this device, the handles are placed at a predefined angle for optimal palletising.

At the pallet side of palletising Packland offers a wide variety of products. Among others it includes pallet destackers, in and out feed roller conveyors, traverse wagons, pallet chain conveyors, turn tables, etc. Also integrating a pallet wrapper and/or labelling system is a possibility.