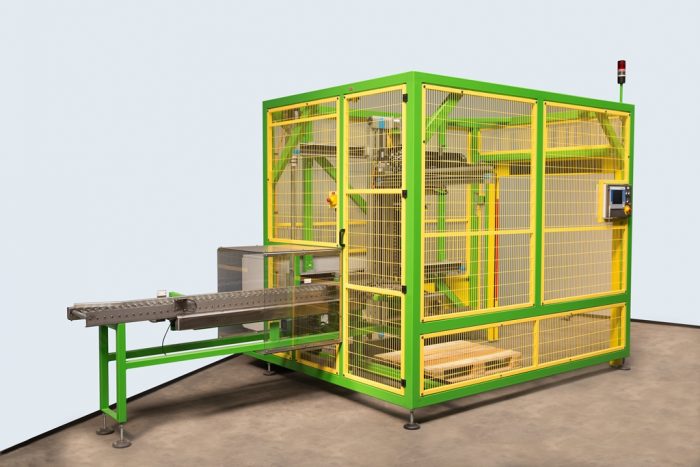

Packland Flex Portal

The Packland Flex Portal / CE palletiser stacks boxes, buckets and cans on pallets. Optionally this machine can be equipped with automatic pallet in and outfeed. This palletiser is perfectly suitable to place behind a Packland PP6 case packer or Packland Smartpack. Stacking patterns can be easily created and saved on the HMI, this garantees optimal flexibility. Because the axis in this machine are on the side, the machine has a total height of only 2525mm.

The products are fed into the machine via an accumulating conveyor. In the machine the products are pushed in the desired pick up configuration. The 4-axis robot arm uses vacuum or grippers to place the products on the pallet.

- The product infeed conveyor is driven by an electro motor.

- The robot arm is driven by servo drives, for optimal precision and speed.

- The machine is standard equipped with product picked up detection and pallet height measuring.

- Compact and ergonomically accessible

- Solid welded steel frame finished with a PU coating

- Complete manual and built in accordance with CE requirements

- The machine is PLC controlled and equipped with a touch screen for operation and for displaying error messages

- The touch screen features a USB connection for the download and upload of data

- Also, the PLC has a connection for a TCP / IP connection. If required, we can send updates via this link

- Change over into another format is an easy operation: change the gripper/vacuum end of arm tool and change the program on the HMI. The change over time is approximately 3 minutes, and without tools

Technical specifications:

| Machine speed | Maximaal 7 slagen per minuut, afhankelijk van configuratie |

| Maximum product weight | 25kg |

| Machine dimensions | approx 3240 x 1990 x 2525 mm (L x W x H) without options |

| Compressed air | 6 bar, clean dry air |

| Air consumption | approx 400L/m, depending on gripping solution |

| Supply voltage | 400V – 3 phase / N / earth 50Hz, others on request |

Options:

- 90 degree turned infeed

- pallet magazine and pallet outfeed conveyor

- vacuum turbine to create vacuum

- orientator to orientate containers with handle

- change part rack

- other requirements in consultation